Installation Guide

The Buteline Plumbing System is designed to be used with complete confidence. You will get a simple, controlled, accurate joint every time.

Step 1. Cut Buteline Pipe

Always use a Buteline pipe cutter to ensure a square, clean, burr-free cut. Cut the pipe on an indicator line.

To assist the pipe cutting process, slightly twist the pipe as you begin to cut.

View Buteline Pipe Cutters play_arrow

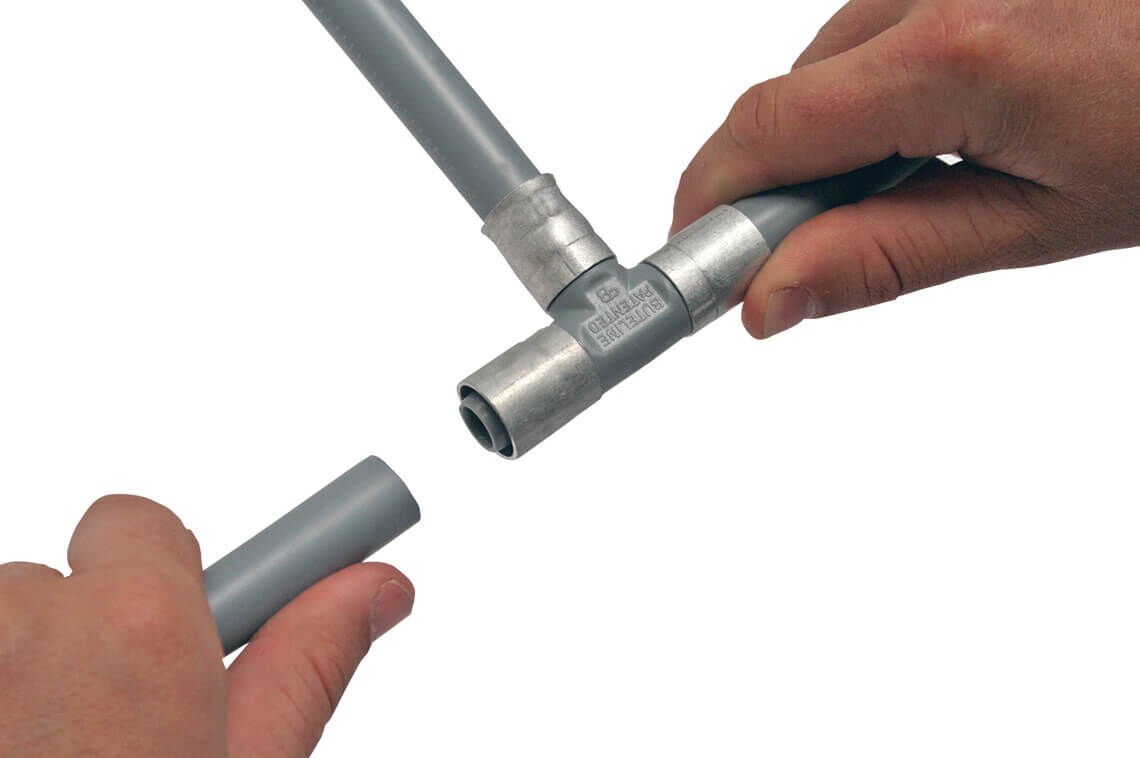

Step 2. Insert Pipe into Buteline Fitting

Once you have cut the pipe, simply insert the pipe into the Buteline fitting and push fully home to the shoulder of the fitting, with a slight twist to 'SureFit', up to the next indicator line of the same size.

View Buteline Fittings play_arrow

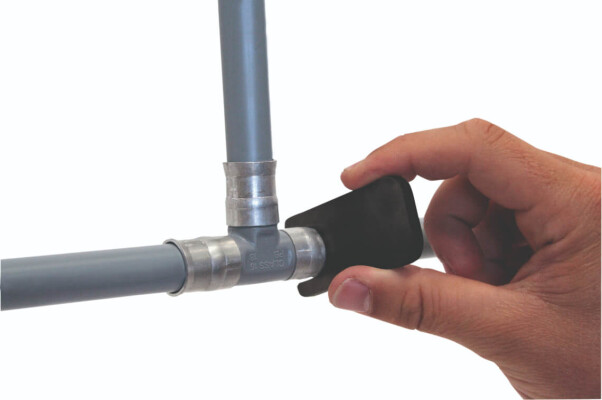

Step 3. Clamp Fitting

Clamp the Buteline fitting, using ONLY the Buteline clamp tool.

Position the Buteline clamp tool squarely, approximately 2mm in from the end of the clamp ring.

Close handles to stops, hold in the tightly closed position for a moment to ensure that the flow of material is performed. Open and remove the tool.

* When burying Buteline fittings underground or when in contact with concrete (or when using for marine purposes), wrap the aluminium rings directly with PVC insulation tape or similar to prevent corrosion.

View Buteline Clamp Tools play_arrow

Step 4. All Complete

Installing the Buteline Plumbing System is quick and sure and always provides a visual indicator of joint completion.

As you can see, the process of using the Buteline system is quick, simple and highly efficient.

Plumbers Technical & Installation Manual

The Buteline Plumbers Technical & Installation Manual can now be viewed online or downloaded. It contains production information, installation guidelines, and helpful advice as well as technical data.

Use the gauge provided with ProClamp Tools, QuickClamp Tools & 28mm Clamp Tools to check that the full clamp force has been achieved. It is important that the gauge passes over the clamp ring. If necessary, take corrective action by re-adjusting the tool and re-clamping.

Service your clamp tool by cleaning and oiling moving parts regularly (WD40 is an ideal cleaner/lubricant). Watch this demo on how to check your standard FR (non-adjustable) clamp tool.