Gasline Fittings

Buteline have developed an extensive range of quality fittings which have complete compatibility with Gasline MLP pipe, and are classified as a permanent joint in accordance to AS/NZS 5601.

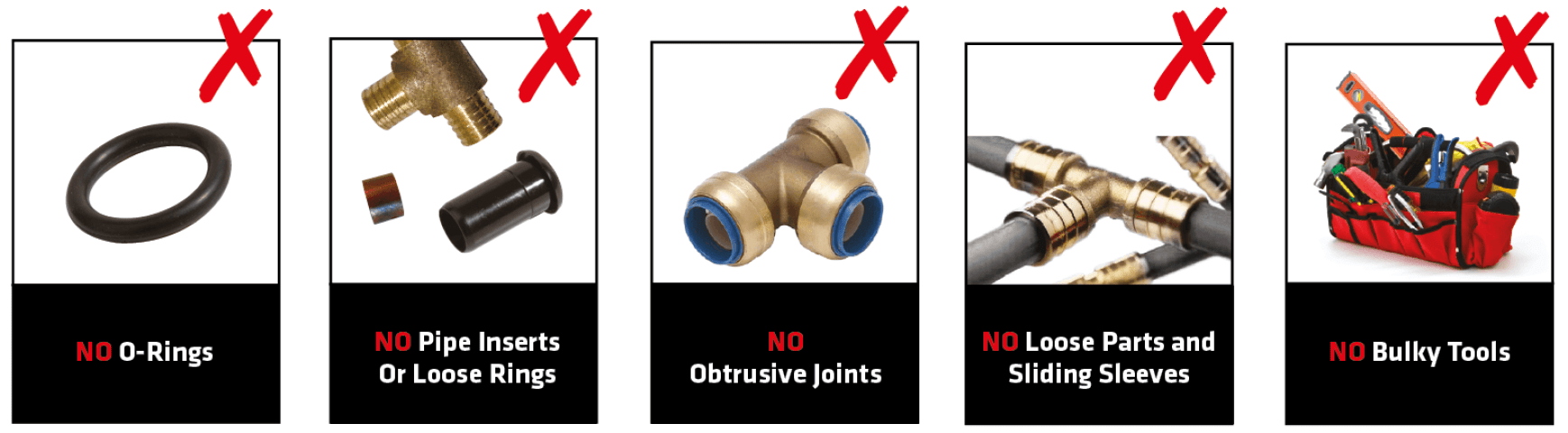

The fittings are made from DZR brass and the annealed aluminium clamp ring is precisely attached to each fitting during production and is designed to provide a unique metal reinforced joint.

Users of Gasline fittings will therefore find the total concept much quicker and more economical than other available systems.

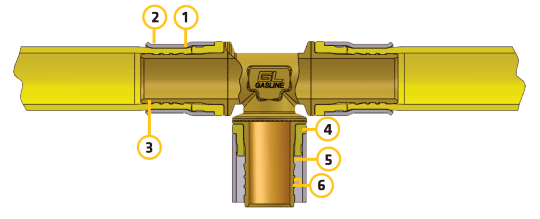

1. 8mm WIDE FORGED CLAMP - Minimum working stress applied (approx. 0.5 ton per sq. in.) allowing pipe material to “flow” into insert tail grooves.

2. 2mm WIDE FLARE - No stress from clamping transmitted to insert tail or pipe at end of fitting. End of metal sleeve cannot impinge into pipe, even when bending.

3. TAPERED ENTRY, SMOOTH BORE - Minimises resistance to flow.

4. POLYMER MOUNTING RING - Positioned between aluminium ring and brass fitting body to eliminate galvanic corrosion.

5. SUREFIT BARB - Patented design feature prevents pipe from falling off sleeve, ensures precise positioning.

6. SEALING RIBS - Narrow lands with wide grooves ensure clamp stress is transferred into the pipe joint efficiently.

Why Choose Gasline Fittings

Learn more about the Gasline installation process

The installation process for Gasline is very quick and simple, and always provides a visual indicator of joint completion: Simply cut and ream, insert, clamp, complete!

Download the Gasline Manual play_arrow